I’m going to tell you about one of the most enjoyable things I did during my recent trip to Italy – Watching the production of Provolone Valpadana cheese at the Auricchio factory in Cremona. Cremona is a city in Northern Italy that is known for its musical history and traditions, and is the heart of the Provolone production zone. One of the oldest cheese making companies in the city is Auricchio. The Provolone cheese they produce, called Provolone Valpadana, has been conferred the P.D.O. (Protected Designation of Origin). Like the title suggests, the entire sourcing, production, and processing takes place only in that defined geographical area – Northern Italy, in this case.

The story goes that Gennaro Auricchio invented a special type of rennet (milk coagulant) which was called Don Gennaro’s “secret”. This is what gives Auricchio Provolone its unique flavor. While Auricchio does produce other types of cheese, its name has become synonymous with Provolone cheese.

A morning at the cheese factory…

As soon as I wore the hairnet and paper-y coat, and covered my boots with plastic, I was beaming. This was my Cheese Slices moment. Something I’d only seen on television up until this point. I was entering my Disneyland.

Early every morning the milk delivery trucks roll into the factory. The whey from the previous day’s cheese making process, along with some rennet, is added to the milk – calf rennet for dolce (mild) cheese, and goat rennet for piccante (strong). Once the curd is formed, the slabs are left to rest for 2-5 hours.

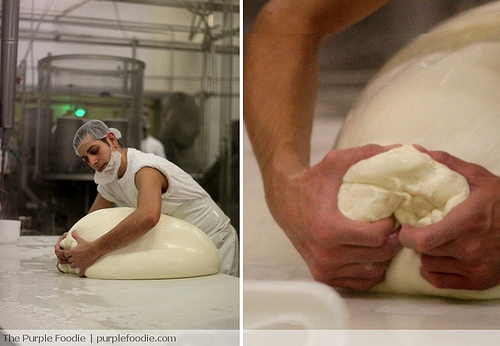

The cheese curd is then put through a machine to obtain the stretched curd. This is the most important step in the production of Provolone Valpadana. The action is known as “filatura”, and the resultant curd is called, “formaggio a pasta filata”. (below, right)

Usually, two men pair up to knead the fresh cheese. PS: Any fuzziness in the photos that you might see is wholly attributed to the steam from the boiling water.

They knead the cheese (what a work-out), and as they’re doing so they keep pouring hot water over it. Almost boiling water. Which is why you need these strong men to take charge. Of course, they knead some love in as well.

Next, it’s time to shape the cheese. They either roll it up into a cylinder (left) to fit into the mould, or shape it by hand.

The moulds are then transferred into a big machine that will submerge them into cool salted water to harden the form. This takes just a few hours.

Depending on the size of the cheese, it is left in the brine for 2hours – 15 days.

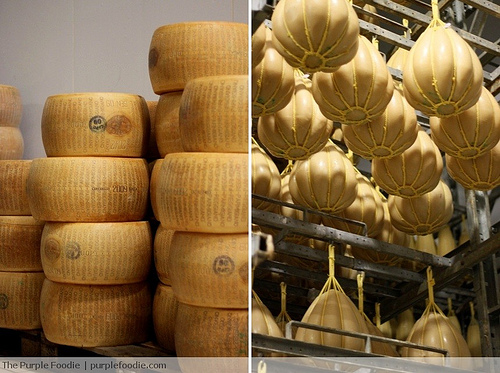

The Provolone cheese is ready to be aged. Again, the maturation time depends on the size of the cheese. Typically, the Dolce(mild) Provolone Valpadana is aged for a maximum for 5-6 months and the Piccante(Strong) is aged for 6 months – 1 year.

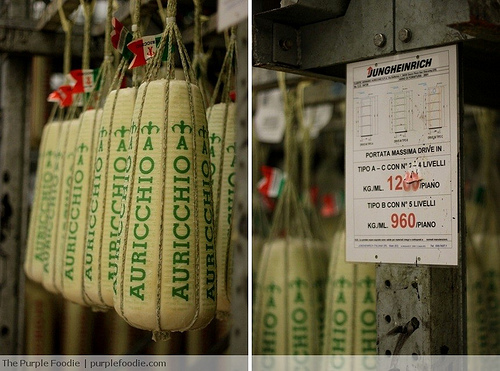

The cylinders of cheese are then tied up snugly, ready for ageing.

Ta-da! Auricchio Provolone ready for consumption.

Smoked provolone.

Walking through the Auricchio, I was overwhelmed. Cheese as far as the eye can see. Cheese from floor to ceiling.

More cheese: Parmigiano Reggiano and Provolone mandarino. While the Grana Padano and Parmigiano Reggiano are not produced here, they are packaged in the same plant.

What we couldn’t photograph was the packaging process. But I can tell you that I was left utterly amazed by the efficiency, accuracy, and technology used.

Aaand then, finally, it was tasting-time! We sampled the dolce, piccante, affumicato (smoked) Provolone as well as peppery Pecorino, Parmiggiano Reggiano. Needless to say, we didn’t really need lunch after.

This trip to Italy was sponsored by the Italian Government and the EU as a part of the European Art of Taste (EAT) Program.